Manufacturers face several challenges with inventory control, some of which include

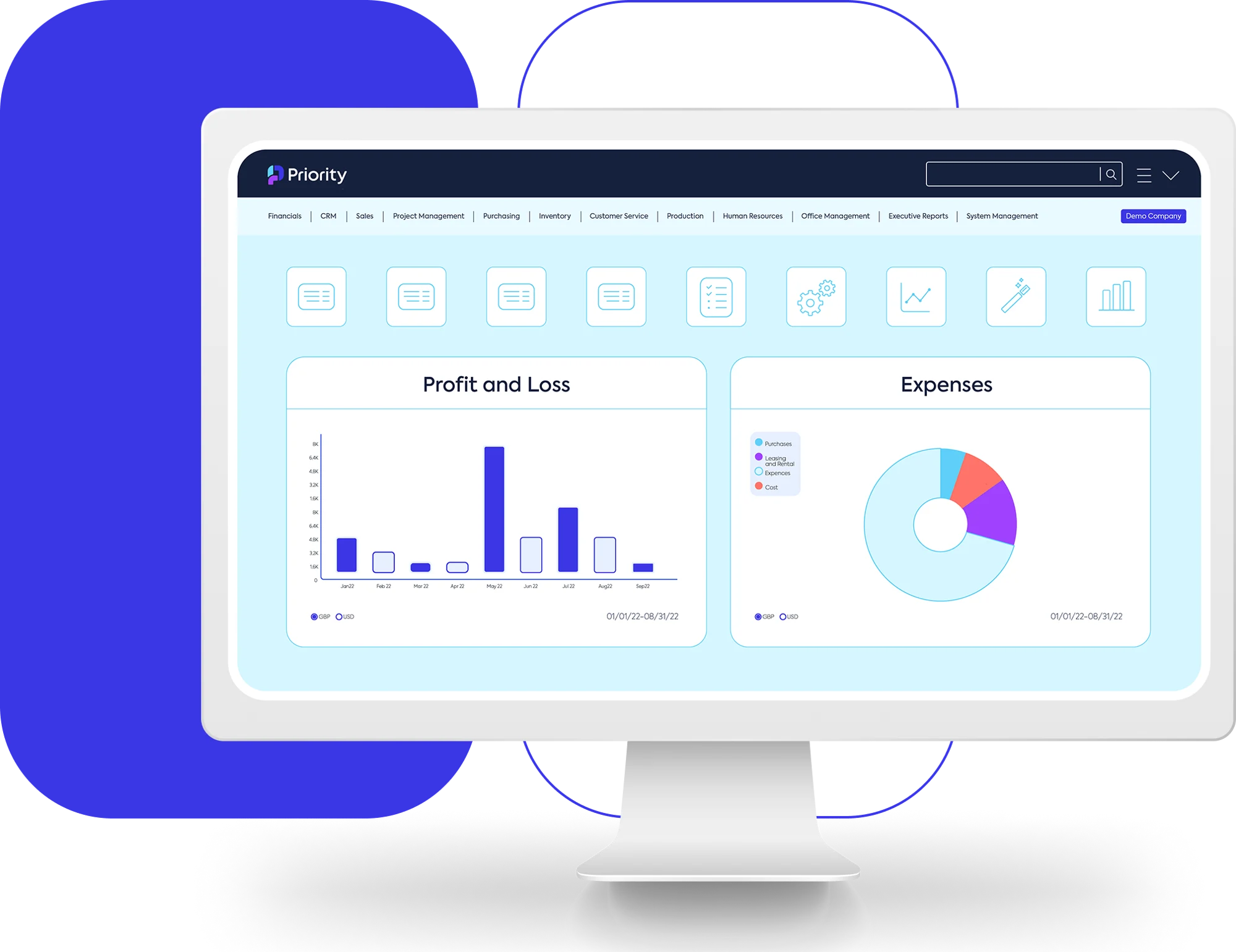

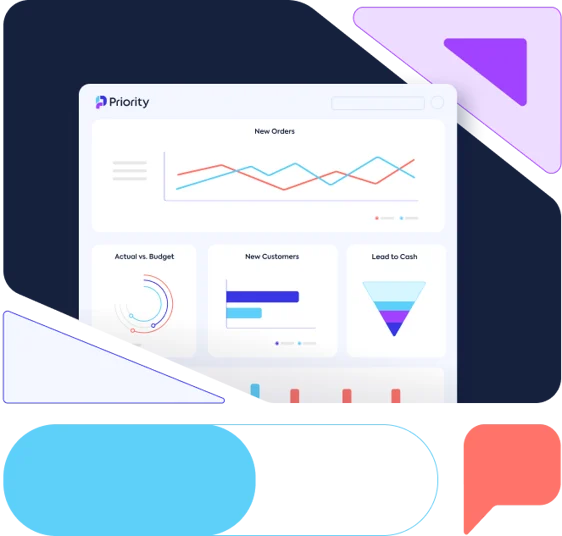

Optimize Your Manufacturing Operations with Priority’s ERP Software

Automate manual tasks, improve communication, and increase profitability

Streamline Manufacturing Operations for Increased Profitability

Optimize your manufacturing operations with features designed to automate manual tasks, provide real-time data and analytics, improve communication and collaboration across departments, and ultimately increase profitability by eliminating inefficiencies.

Priority’s Production Control Module Manages the Entire Manufacturing Process

Optimized production schedules based on demand forecasts and inventory levels

Increased Competition: As more companies enter the manufacturing market, there is higher competition for customers, which can drive down prices and reduce profit margins.

International Trade: With global competition, manufacturers may face pressure to reduce prices to remain competitive. Additionally, tariffs, import/export regulations, and exchange rates can impact profit margins.

Rising Costs: Manufacturing involves many expenses, such as raw materials, labor, and equipment. If these costs increase, it can reduce profit margins unless the company can raise prices.

Technology: As technology evolves, manufacturers may need to invest in new equipment or software to remain competitive.

Changes in Consumer Demand: If consumer demand for a particular product decreases, the manufacturer may need to lower prices to remain competitive. This can result in lower profit margins.

Priority’s ERP Streamlines the Manufacturing Process

Improved productivity through automation of repetitive tasks

Complete transparency into every aspect of your operation

Data-driven decision-making with real-time access to key metrics

Streamlined supply chain management to minimize disruptions

Increased customer satisfaction through faster and more accurate deliveries